Xinhui Metal Products offers a wide stock of Crimped Wire Mesh or Crimped Wire Netting in different materials like Stainless Steel Crimped Wire Mesh and weaving patterns. There are many applications of the crimped mesh, such as mining, construction, petrochemical, cement, food processing ,inner and outside building decoration and many others. These mesh screens have got excellent consistency as the wires are pre-crimped before weaving into meshes. The metal used in designing is of superior grade and hence makes the wire mesh adaptable to the heat, cold, chemicals, acids and load involved in the industry.

The Pre-crimped process

Using the precision machine, the intermediate crimped wire is pre-crimped by the rotary dies. The pre-crimped wire can assure the spacing of the wires. When the wires are woven together, the structure can ensure the wires will lock firmly together at the intersections. The pre-crimped weaving method can assure the accurate open area and make the structure stability and smooth.

The Double Crimp, Intermediate Crimp, Flat Top Crimp, and Lock Crimped Weaving Method

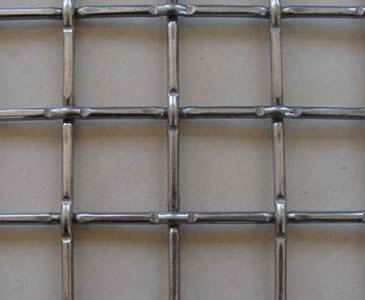

Flat top crimped

Flat top crimped, also called pressed crimped, is made from round and profiled plain weave wire. All the mesh knuckles is being on the underside. The structure is very heavy and durable. The smooth surface is the characteristic of the weaving method. This structure can allow the materials to move more freely over the screen. It is widely used in the vibrating screen.

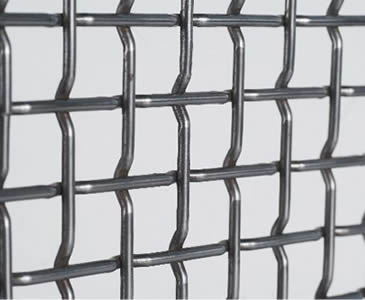

Lock crimped

Lock crimped is a refinement of the intermediate crimped. It can lock the wire at their position through pressed at each side of the raised wire. This structure can add the stability of the crimped woven wire mesh.

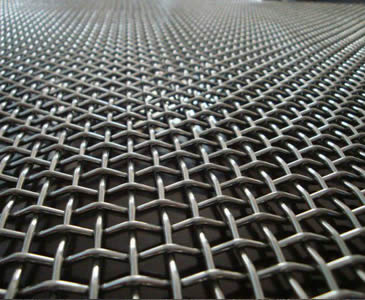

Double crimped

Double crimped is also called plain weave. Different from the intermediate crimped, both the warp wire and weft wire are woven directly by straight wire. We can get a rigid construction through evenly crimp in warp and weft wire. The wires are under crimped and sprung together thus giving a tight mesh. This is used mainly with lighter wires to ensure tension in a light screen.

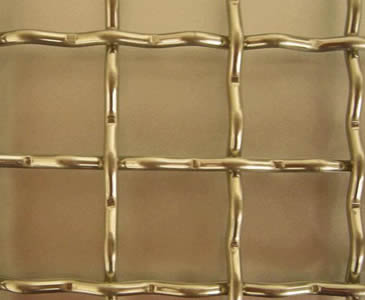

Intermediate crimped

Intermediate crimped can be divided into single intermediate crimped and double intermediate crimped.

The single intermediate crimped means the weft wire is pre-crimped and the warp wire is directly woven. The double intermediate crimped means both the weft wire and warp wire is pre-crimped and then woven together.

Specification

Material: stainless steel wire, spring steel wire, manganese steel wire, galvanized wire, copper wire.

Weaving method: double crimped, flat top crimped, intermediate crimped and lock crimped.

Mesh type: square mesh and rectangle mesh.

Edge type: plain, bent and reinforced hooked.

Light type crimped woven wire mesh

Mesh size: 2 mesh - 22 mesh.

Width: 1m - 2m.

Length: 30m.

Heavy duty crimped wire mesh panel

Mesh size: 2mm - 30mm.

Wire diameter: 1mm - 6mm.

Width: 1m.

Length: 2m.

Rectangle pig raising mesh

Material: carbon steel wire, galvanized steel wire and stainless steel wire.

Wire diameter: 3.8mm - 8mm.

Opening size: 10mm × 50mm, 11mm × 50mm, 8mm × 50mm

Mesh width: max. 2m.

Barbecue grill mesh

Wire diameter: 0.4mm - 3.0mm.

Aperture size: 1mm - 15mm.

Mesh diameter: 230mm, 240mm, 260mm, 270mm, 280mm, 300mm, 350mm, 400mm, 500mm.

Features

Corrosion and rust resistance.

Acid and alkali resistance.

Strong structure. Pre-weaving crimped wire.

Applications

Crimped woven wire cloth can be used as pig raising mesh.

Crimped woven wire mesh can be used for the protective screens for the machines.

Crimped woven wire mesh can be used as fences for the workshops, stairs.

Crimped woven wire cloth can be used as barbecue grill mesh for the restaurants, camping and travels.

Heave duty crimped woven wire mesh can be used as the woven wire vibrating screen in the mining, coal and other industries.